Panel alignment procedures are essential in vehicle dent repair and car service industries, aiming for precise metal panel realignments post-collision. Skilled technicians, armed with specialized tools, ensure both functional and aesthetic accuracy, preventing future issues and maintaining optimal vehicle performance. Efficient processes, facilitated by advanced equipment and systematic approaches, significantly shorten repair times, enhancing overall collision repair outcomes while benefiting repair shops and customers alike.

Panel Alignment Procedures are integral to efficient automotive repairs, significantly influencing service timeframes. This article delves into the intricacies of these procedures, exploring their role in streamlining workflows and reducing turnaround times. We’ll dissect the process, analyze its impact on repair efficiency, and offer best practices for optimal alignment, ensuring high-quality outcomes while minimizing wait periods for vehicle owners. Understanding these procedures is key to mastering efficient auto service.

- Understanding Panel Alignment Procedures

- The Impact on Repair Time Frames

- Best Practices for Efficient Alignment

Understanding Panel Alignment Procedures

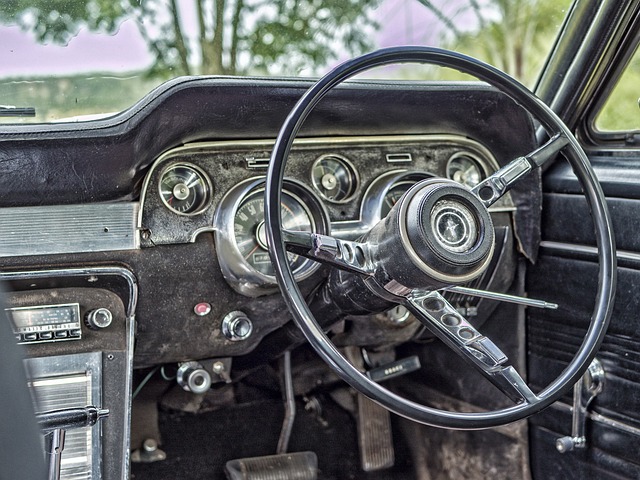

Panel alignment procedures are a critical step in the process of vehicle dent repair and car repair services. These processes involve precisely realigning and resetting metal panels to their original factory-spec positions after a vehicle collision repair. By ensuring that all components are correctly aligned, panel alignment procedures play a pivotal role in achieving seamless aesthetics and structural integrity.

Effective panel alignment is essential for both functional and visual accuracy. It helps prevent future issues like misaligned doors or fenders, ensuring the vehicle’s overall performance remains optimal. Skilled technicians use specialized tools and techniques to carefully manipulate panels back into place, often with millimeter precision. This meticulous approach not only shortens repair time frames but also enhances the quality of vehicle collision repair outcomes.

The Impact on Repair Time Frames

The efficiency and effectiveness of panel alignment procedures play a pivotal role in dictating repair time frames for auto bodywork and auto collision repair. These processes are fundamental to ensuring that damaged components are restored to their original specifications, thereby facilitating a seamless integration into the vehicle’s overall structure. When executed meticulously, panel alignment can significantly expedite the repair process, enabling faster turnaround times for tire services and other critical repairs.

In the realm of auto collision repair, accurate panel alignment is crucial for achieving aesthetic perfection and structural integrity. It prevents misalignments that could lead to long-term issues, ensuring that the vehicle not only looks good but also performs optimally on the road. Efficient panel alignment procedures thus serve as a game-changer, transforming what could be a lengthy process into a streamlined, effective procedure that benefits both repair shops and their customers.

Best Practices for Efficient Alignment

Efficient panel alignment procedures are a cornerstone for reducing repair time frames, particularly in busy automotive workshops handling numerous car collision repairs and fender repairs. To streamline this process, best practices include investing in advanced equipment like precision alignment machines that minimize manual adjustments. Technicians should also undergo regular training to stay updated with the latest techniques and safety protocols, ensuring consistent and accurate results.

A systematic approach is vital. This involves meticulously documenting each step of the alignment process, using specialized software to track progress and identify potential issues early on. Maintaining a clean and organized workspace further enhances efficiency, minimizing the risk of errors that can lead to costly frame straightening mistakes.

Panel alignment procedures play a pivotal role in reducing repair time frames. By understanding these processes and implementing best practices, teams can streamline their work, optimize efficiency, and ultimately deliver faster repairs without compromising quality. Efficient panel alignment is not just about technique; it’s a strategic approach that impacts overall job completion times and client satisfaction.